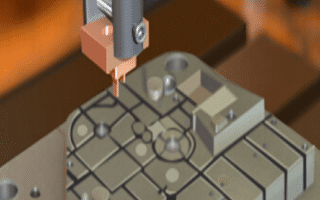

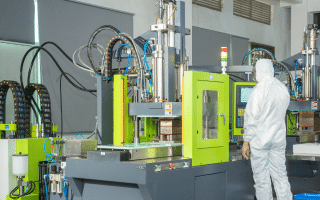

Gas assisted injection molding

We have a professional gas-assisted injection mold design team and manufacturing equipment. We can provide customers with injection design and gas-assisted molding solutions for high-end injection molding machine components. Our engineering team can provide customers with high-quality injection molded parts to reduce the internal stress of the product, reduce warpage deformation, and improve the strength of the product. The plastic material is molded under the same molecular structure to improve the rigidity of the product.

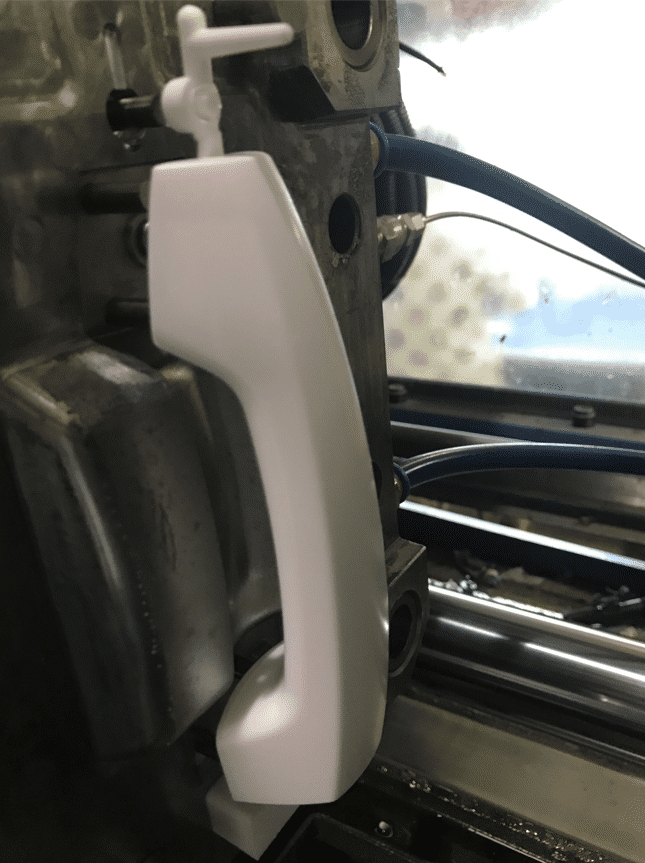

Win Industry can provide gas-assisted mold making and injection molding services. It will utilize pressurized nitrogen gas injected into the mold during the process. Nitrogen moves the molten plastic to the outside of the mold walls while the plastic parts in designated areas can be hollowing out. It is ideal for medical device housings and handles, automotive door handles, steering wheels, and electronic device housings with thick wall designs.

Advantages

● May use less raw material

● Less warping and distortion

● Less weight

● Decrease cycle time

● Eliminate sink marks and surface imperfections

● Increase the strength and stiffness of parts

● Improve design options, warpage and appearance issues

Application fields

Gas-assisted plastic injection molding applications include:

● Home appliance handles

● Medical equipment casing

● Car handles

● Large cover plates and panels for office equipment

● Steering wheel

● Thick plastic housing with ribs and boss

● Plastic chair

● Any plastic tubular part with hollow interior (hollow interior reduces weight)

Please fill out the form below to discuss your tooling and production needs.